Unleash your creativity with TsukishiroShooting.

Unleash Your Creativity with INARI

"INARI P35" is a Pneumatic injection molding machine driven by an air cylinder. The concept of making injection molding easy is the same as the manual "INARI", but we aimed to achieve more stable molding quality and support a wider range of materials.

With simple handle operation and a single switch, anyone can perform high-quality molding. With a pressure capacity of approximately 2 tons and a heating temperature of up to 320°C, it can also mold engineering plastics including polycarbonate. From prototyping in research and development, to molding tests of new materials, to small-scale production of products, it expands all possibilities of manufacturing.

Features

Easy to use and simple to operate

The operation of the "INARI P35" is extremely simple. Just insert the pellets, set the mold, tilt the handle towards you, and press the switch. No complicated operations are required, and anyone can produce stable, high-quality molding.

Large mold setting table with preheating function

Although it is a compact tabletop machine, the table has a mold installation area of 400mm x 183mm x 80mm. Large molded products can be produced, greatly expanding the range of designs. In addition, it is equipped with a mold preheating function, and detailed molding conditions can be set, allowing for high-quality molding.

We also handle a wide range of engineering plastic moldings.

The "INARI P35" has a pressure capacity of approximately 2 tons and a maximum heating temperature of 320°C. It is capable of molding engineering plastics including polycarbonate, and is compatible with manufacturing using a wide range of materials.

Simple structure that allows easy introduction of new materials

The structure is simpler than that of a typical large injection molding machine, so there is no need to worry about major problems when feeding materials. You can easily feed in a variety of materials, from materials containing fillers to waste plastics such as PET bottle caps. It is also ideal for molding tests of new materials.

Designed to enable molding with resin molds

In a typical injection molding machine, the material is injected while the cylinder is pressed against the mold. With this method, the force pushing the press shaft is transmitted directly to the mold via the cylinder, increasing the possibility of deformation or damage to the mold.

"INARI P35" inherits the structure of the conventional "INARI" series, which separates the "force to press the mold" from the "force to press the material". This unique structure realizes high pressure capacity while minimizing the burden on the mold. It is also possible to mold with resin molds made by 3D printers, making molding easier.

Engineer: Hiroki Akitsu

Editor: Hibiki Yaegashi

Photographer: Kota Sugawara

We are accepting reservations for tours for customers who are considering purchasing the "INARI P35."

■ Related keywords

Small injection molding machine / Home injection molding machine / Homemade injection molding machine / Small plastic molding machine / Micro molding machine / Small injection molding machine / Small injection machine / Desktop injection molding machine / Home injection molding machine

Dimensions

External dimensions

cylinder dimensions

Mountable mold size

Product composition

INARI P35 main unit

heat resistant gloves

Safety goggles

Click here to see what else you need to prepare.

Specifications

Materials with proven molding experience

Materials with proven molding experience

General purpose plastics: PP, PS, HDPE, LDPE, ABS, TPE, EVA, PMMA, PVA

Engineering plastics: PC, PBT, PA6, PA66, POM, COC

PBT can be molded into cylinders with an inner diameter of Φ10 or Φ15. PC can only be molded into Φ10.

Sustainable materials: Cellulose resin, rice resin, LIMEX, PLA, PBS, cellulose acetate resin

Maximum throughput

Maximum throughput

Cylinder inner diameter Φ10: 8cc / Φ15: 20cc / Φ20: 35cc

Heating temperature upper limit

Heating temperature upper limit

320℃

Pressure method

Pressure method

Pneumatic using air cylinder

Air compressor required separately

Operating air pressure range

Operating air pressure range

0.2MPa ~ 1.0MPa

Recommended pressure range 0.2MPa to 0.6MPa

Maximum pressurizing capacity

Maximum pressurizing capacity

Approximately 2 tons

Mountable mold size

Mountable mold size

Thickness 10 to 80mm

power supply

power supply

AC100V 50/60Hz

power consumption

power consumption

800W

Body weight

Body weight

100kg

Specifications for each cylinder size

The heating cylinder of the "INARI P35" is replaceable and is available in three sizes: Φ10, Φ15, and Φ20. Please use the appropriate size cylinder depending on the material used and the size of the molded product.

Φ10 (Maximum extrusion amount: 8cc)

The smaller the maximum extrusion volume, the higher the pressure capacity per area. It is suitable for molding materials with extremely low fluidity, such as polycarbonate (PC).

Φ15 (Maximum extrusion amount: 20cc)

This cylinder size has a good balance of extrusion volume and pressure capacity, and is highly versatile. Although it is difficult to mold polycarbonate (PC), most other materials can be molded.

Φ20 (Maximum extrusion volume: 35cc)

The larger the maximum extrusion volume, the lower the pressure capacity per unit area. It is suitable for making large molded products using highly fluid materials such as polypropylene (PP), polyethylene (PE), and elastomers (TPE).

Compatible materials list

| General Purpose Plastics | Cylinder Inner Diameter | ||

|---|---|---|---|

| Φ10 | Φ15 | Φ20 | |

| P.S. | ● | ● | △ |

| PP | ● | ● | ● |

| ABS | ● | ● | ● |

| HDPE | ● | ● | ● |

| LDPE | ● | ● | ● |

| TPE | ● | ● | ● |

| EVA | ● | ● | ● |

| PMMA | ● | ● | △ |

| PVA | ● | ● | ● |

| Engineering Plastics | Cylinder Inner Diameter | ||

|---|---|---|---|

| Φ10 | Φ15 | Φ20 | |

| PC | ● | ||

| PBT | ● | ● | |

| PA6 | ● | ● | ● |

| PA66 | ● | ● | ● |

| POM | ● | ● | ● |

| COC | ● | ● | ● |

| Sustainable Materials | Cylinder Inner Diameter | ||

|---|---|---|---|

| Φ10 | Φ15 | Φ20 | |

| Selbren | ● | ● | ● |

| rice resin | ● | ● | ● |

| LIMEX | ● | ● | ● |

| PLA | ● | ● | ● |

| PBS | ● | ● | ● |

| Cellulose Acetate Resin | ● | ● | |

Molding Pressure Table

| Operating pressure (MPa) | Cylinder Inner Diameter | ||

|---|---|---|---|

| Φ10 | Φ15 | Φ20 | |

| 0.2 | 96 | 43 | 24 |

| 0.3 | 144 | 64 | 36 |

| 0.4 | 192 | 85 | 48 |

| 0.5 | 240 | 107 | 60 |

| 0.6 | 288 | 128 | 72 |

| 0.7 | 336 | 149 | 84 |

| 0.8 | 384 | 171 | 96 |

| 0.9 | 432 | 192 | 108 |

| 1.0 | 480 | 213 | 120 |

Unit: MPa

We are accepting reservations for tours for customers who are considering purchasing the "INARI P35."

■ Related keywords

Small injection molding machine / Home injection molding machine / Homemade injection molding machine / Small plastic molding machine / Micro molding machine / Small injection molding machine / Small injection machine / Desktop injection molding machine / Home injection molding machine

How to use "INARI P35"

Injection molding used to be possible only with large machines like those found in factories. The INARI P35 is a completely new injection molding machine that can be done on a desk without complicated operations. We will introduce how to use the INARI P35, which makes injection molding easier than ever before and is also ideal for prototyping and molding tests.

What to prepare

- INARI P35

- Air Compressor

- Air hose (1/4 size hose with coupler or hose with outer diameter of Φ12)

- Heat-resistant gloves (included in the kit)

- Resin removal spoon (included in kit)

- mold

- Sprue bushing ( sold here )

- Resin pellets ( sold here )

Types available in INARI P35

In addition to metal molds, you can use resin molds made with 3D printers, etc. When molding with a resin mold, you can use the optional " Mold frame " to prevent deformation or damage to the mold and improve molding quality.

In addition, for customers who want to use a mold but find it difficult to prepare one, we offer a " mold making service ." This service can be used by customers who have 3D data as well as those who do not.

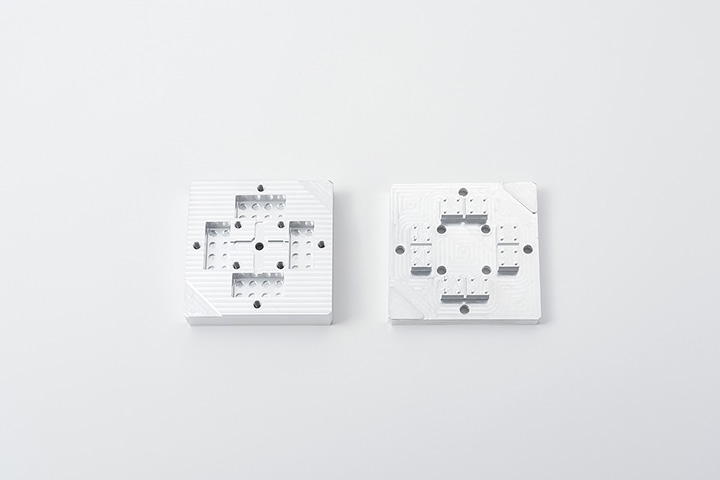

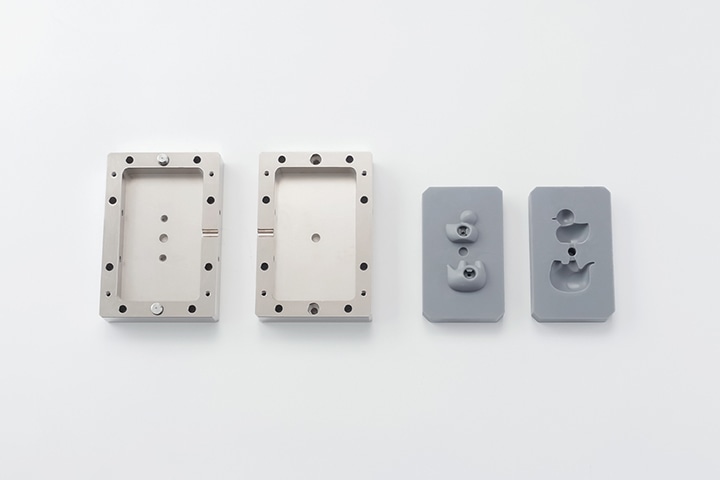

Aluminum mold

Mold frame and 3D printed resin mold

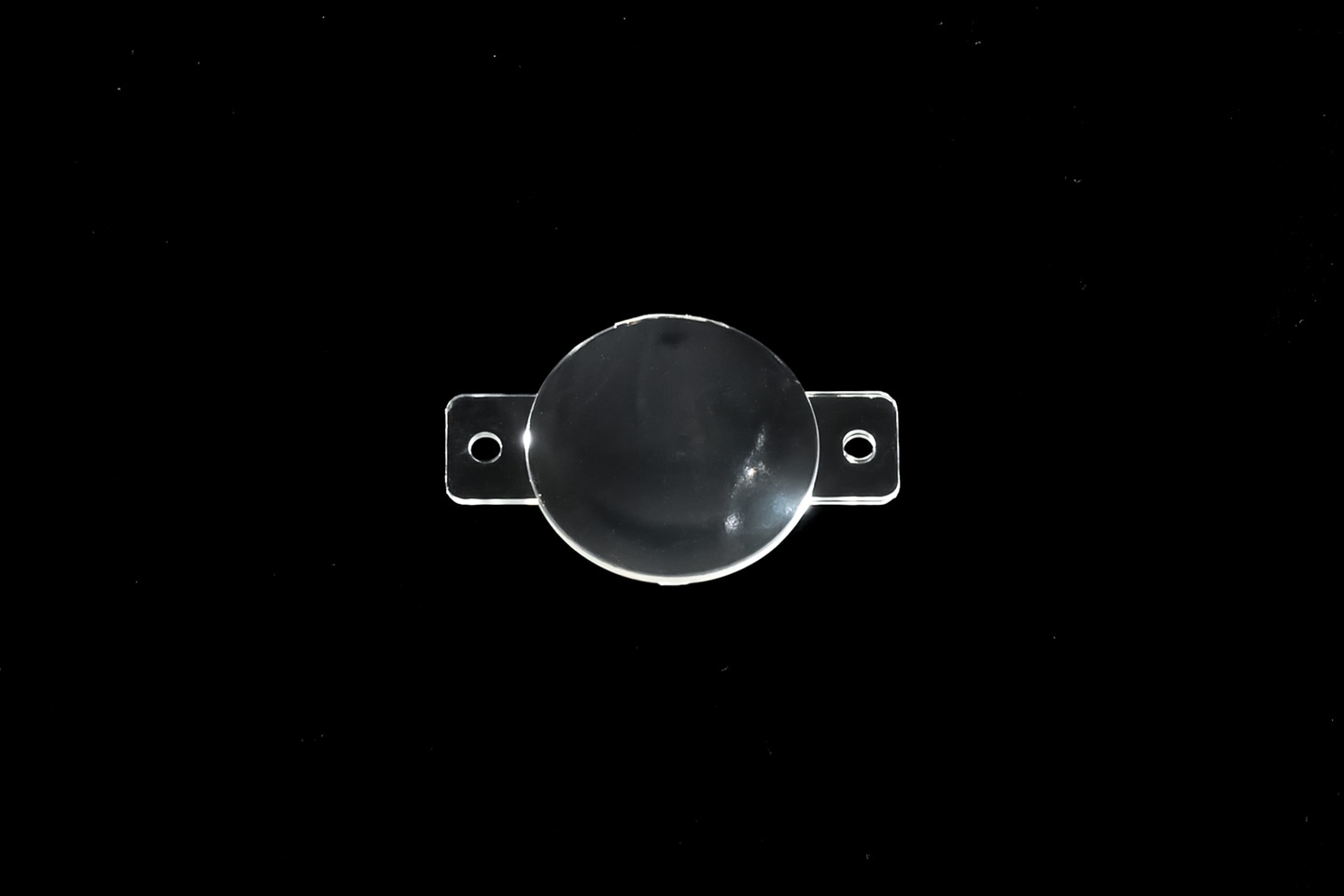

Sprue bushing preparation

By attaching the sprue bush to the mold, the nozzle of the "INARI P35" and the injection port of the mold are in close contact, making molding easier. The nozzle touch R10.5 is compatible.

Sprue bushing ( Go to product page )

Molding using a mold with a sprue bush attached

1. Connecting the air compressor

Connect the "INARI P35" to the air compressor with an air hose. After connecting, turn on the air compressor and fill the tank with air. Once filled with air, open the valve of the air compressor to send air into the "INARI P35".

Precautions when using an air compressor

Please use an air compressor with a maximum pressure of 1.0MPa. The INARI P35 operates within a pressure range of 0.2MPa to 1.0MPa, but for safety reasons we recommend using it within a range of 0.2MPa to 0.6MPa.

2. Heating the cylinder and table

Plug the "INARI P35" into an outlet and turn it on. Set the target temperatures for the cylinder and table, then start heating. The cylinder temperature controller is on the right and the table temperature controller is on the left.

3. Filling with pellets

Pull out the pellet supply port and insert the pellets.

4. Adjusting the injection pressure

The injection pressure is adjusted according to the size of the molded product, the shape of the mold, and the material used.

5. Place the mold on the table

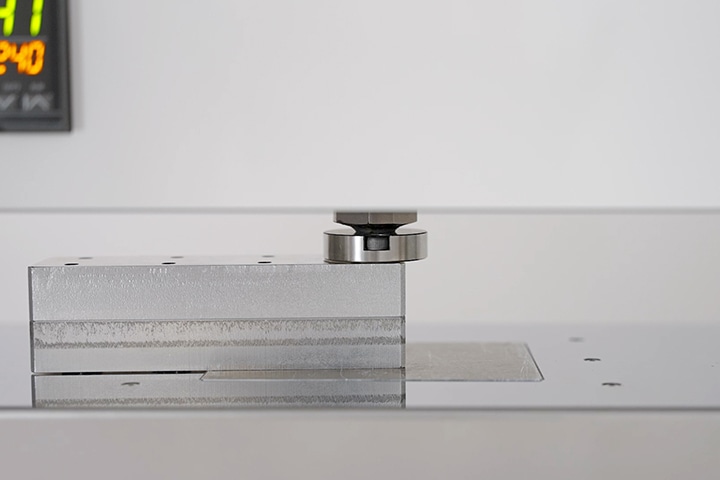

When the cylinder temperature reaches the set temperature and the material comes out of the nozzle, molding is complete. Remove the molten material and place the mold on the table so that the injection port is directly under the nozzle.

How to adjust the table height

The height of the table can be raised or lowered by turning the adjustment screw under the table. Adjust the height so that the nozzle and the injection port of the mold are in close contact when the handle is pulled toward you.

6. Injection

Pull the handle towards you and press the left and right switches at the same time to inject the material. The resin is forced into the mold, and when the injection operation stops, keep pressing the switch for a few seconds to hold the pressure. After a few seconds, release the switch, return the handle to its original position, and then remove the mold.

7. Completion

Remove the molded product from the mold and it's complete.

We are accepting reservations for tours for customers who are considering purchasing the "INARI P35."

■ Related keywords

Small injection molding machine / Home injection molding machine / Homemade injection molding machine / Small plastic molding machine / Micro molding machine / Small injection molding machine / Small injection machine / Desktop injection molding machine / Home injection molding machine

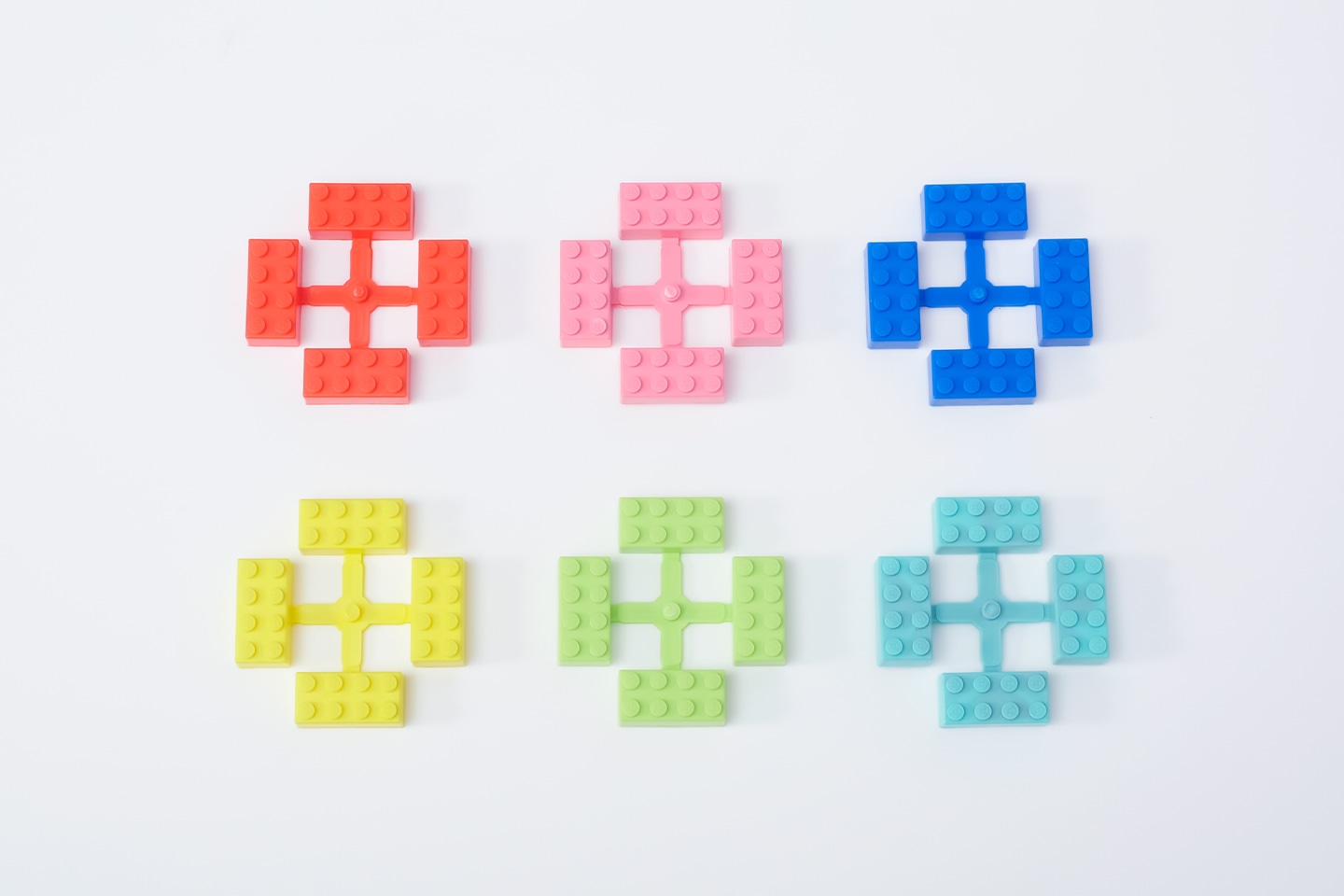

Molded sample

You can see the list of molding samples of "INARI P35". Detailed articles of each sample will be released one after another. Please wait for a while.

We are accepting reservations for tours for customers who are considering purchasing the "INARI P35."

■ Related keywords

Small injection molding machine / Home injection molding machine / Homemade injection molding machine / Small plastic molding machine / Micro molding machine / Small injection molding machine / Small injection machine / Desktop injection molding machine / Home injection molding machine

Tools needed to assemble the kit

Hex wrench

Two-sided widths of 2mm, 2.5mm, 3mm, 4mm, 5mm, and 6mm are required. ( See product page )

+driver

You will need No.0 and No.2.

monkey wrench

A two-sided width of 36mm or more is required. ( See product page )

Wrench

A two-sided width of 28 mm is required. ( See product page )

nipper

It is necessary to cut off the excess of the cable ties that hold the wires together. It is also used to cut gates and shape molded products. We recommend using nippers for plastics. ( See product page )

What Requirements to install the product

Workbench

A load capacity of 100kg or more is required.

What Requirements for molding

Air Compressor

Maximum pressure of 1MPa can be used. Please prepare a tank with as large a capacity as possible. The larger the tank capacity, the less the air pressure drop, allowing for stable molding.

Air Hose

This is required to connect the air compressor to the "INARI P35" main unit. Please prepare one with an outer diameter of Φ12 mm or one with a Japanese standard 1/4 coupler.

mold

In addition to metal molds, molding can also be done using resin molds.

If you prepare a mold , you can use "KitMill" to complete the process from mold production to injection molding on the same day. Mold processing can be done with all models. If you want to improve accuracy, we recommend using the " KitMill AST200 ", which has excellent cutting performance, in combination with the " Coolant Case ".

If it is difficult to make your own mold, we offer a " mold making service ." After processing the mold at our partner company, we will deliver it to you after conducting a molding test. This service is available to customers who have 3D data, as well as those who do not.

When preparing a resin mold

You can make it yourself with a 3D printer. If you are molding with a resin mold, you can prevent deformation or damage to the mold and improve molding quality by placing it in the optional "Mold frame" ( see product page ). For the dimensions of the Mold frame and how to use the spacer, please refer to this PDF .

Even if you don't have a 3D printer, you can easily request the creation of a resin mold by simply uploading 3D data using DMM.make's 3D modeling service, DMM.make 3D PRINT .

Sprue bushing

By attaching the sprue bush to the mold, the nozzle of the "INARI P35" and the injection port of the mold are in close contact, making molding easier. The nozzle touch R10.5 is compatible. ( Go to product page )

pellet

Granular plastic resin used as a raw material for processing. Please choose the one with the characteristics that best suits your purpose. ( Go to product page )

Convenient things to have

Air compressor sub-tank

The tank capacity of the air compressor can be increased. Increasing the tank capacity reduces the drop in air pressure, enabling more stable molding.

Scraper

This is useful for separating molds.

pliers

It is useful for removing molded products from the mold. ( See product page )

cutter knife

It is useful for adjusting the shape of molded products.

Cooler

It is useful for cooling the mold. ( See product page )

When molds are used continuously, heat builds up and the dimensions can be affected depending on the temperature. By cooling the mold, it is possible to continue molding while maintaining accurate dimensions.

We are accepting reservations for tours for customers who are considering purchasing the "INARI P35."

■ Related keywords

Small injection molding machine / Home injection molding machine / Homemade injection molding machine / Small plastic molding machine / Micro molding machine / Small injection molding machine / Small injection machine / Desktop injection molding machine / Home injection molding machine

Tour reservation

We are accepting reservations for tours for customers who are considering purchasing the "INARI" series of injection molding machines. After our staff explains the product, we will demonstrate molding with "INARI". We accept reservations for three slots per week, with each slot lasting one and a half hours from 13:30 to 15:00. Please feel free to apply.

Product catalog

Product catalog

Product catalog

Product catalog

You can view an Summary of the "INARI" series, how to use it, and frequently asked questions.

Mold production agency service (PDF: 1.8MB)

You can view the Summary and costs of our mold production agency service.

We are accepting reservations for tours for customers who are considering purchasing the "INARI P35."

■ Related keywords

Small injection molding machine / Home injection molding machine / Homemade injection molding machine / Small plastic molding machine / Micro molding machine / Small injection molding machine / Small injection machine / Desktop injection molding machine / Home injection molding machine