Filled with unparalleled beauty ,black goldThe highest peak of.

Ultimate Cutting Performance

of

Incomparable Beauty in Black.

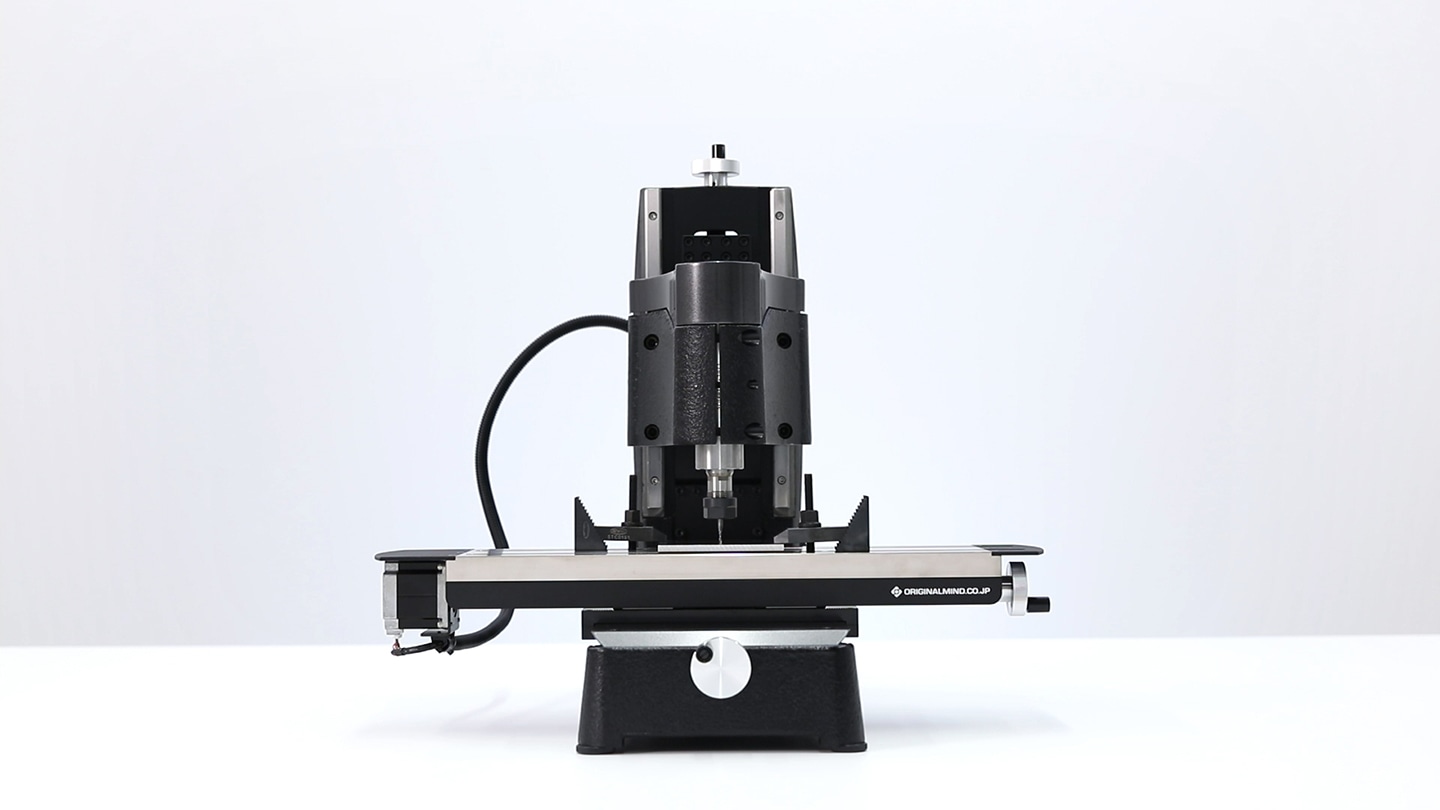

A high-end model in the "KitMill" series that shines with the highest cutting performance and a beautiful and solid design.

By using cast iron for the entire frame, we have achieved unprecedented mechanical rigidity and damping performance. It exhibits stable cutting ability even on steel materials, and achieves unparalleled cutting efficiency when machining light metals and resins. It also has the largest Z-axis stroke in the series, making it suitable for machining tall parts.

Features

Heavy and highly rigid structure

The entire frame is made of cast iron, which has excellent rigidity and vibration damping properties. It has both a beautiful design that shines with the unique texture of cast iron, and functionality that allows for powerful and stable cutting.

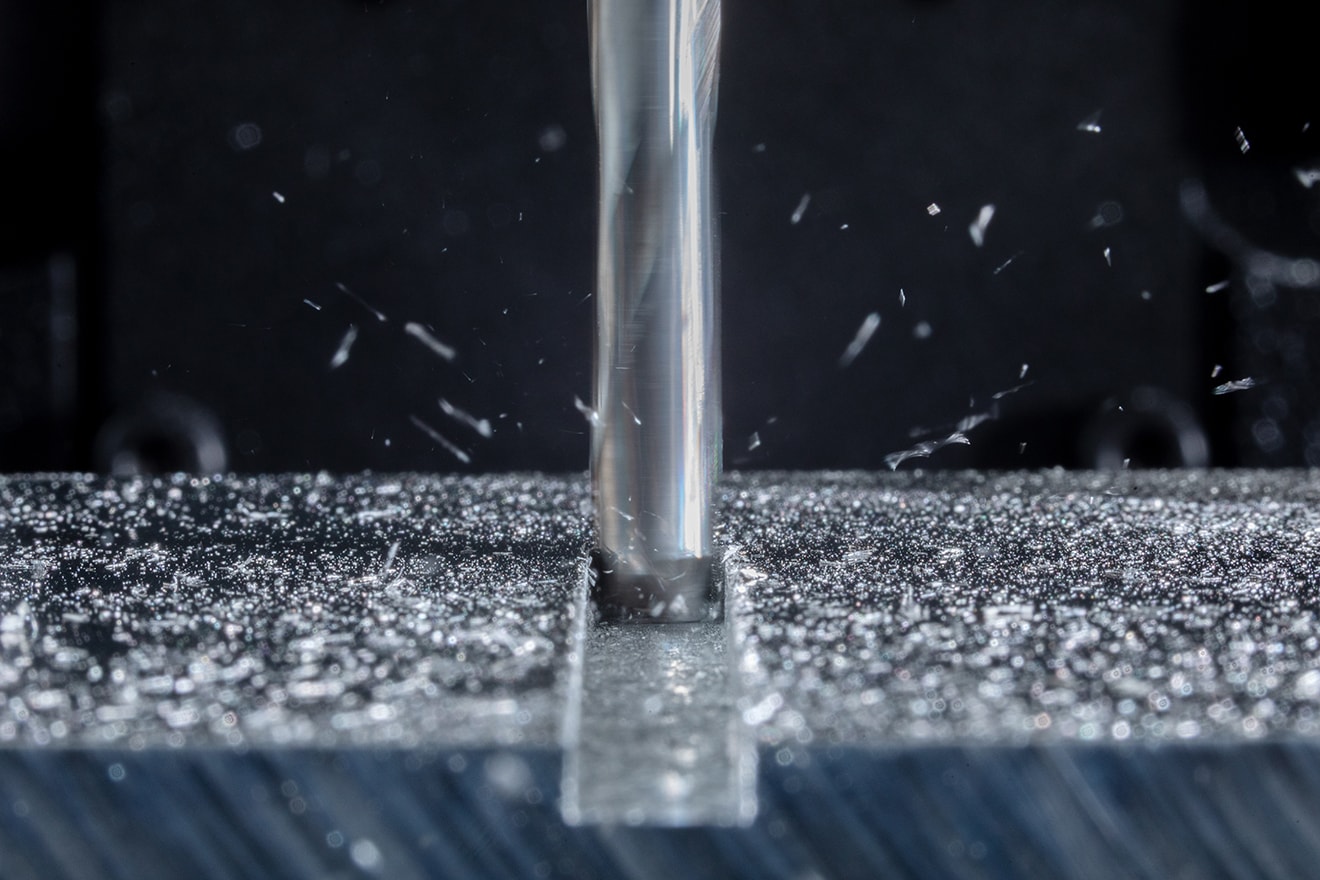

Best cutting performance in the series

In addition to the cast iron frame, the spindle uses a high-output motor, making stable cutting possible even on steel materials. Even when processing light metals and resins, you can experience unprecedented cutting efficiency.

The largest Z-axis stroke in the series

It has the largest Z-axis stroke in the series and is also capable of machining tall parts. It exhibits high cutting ability even for three-dimensional objects and reduces machining time.

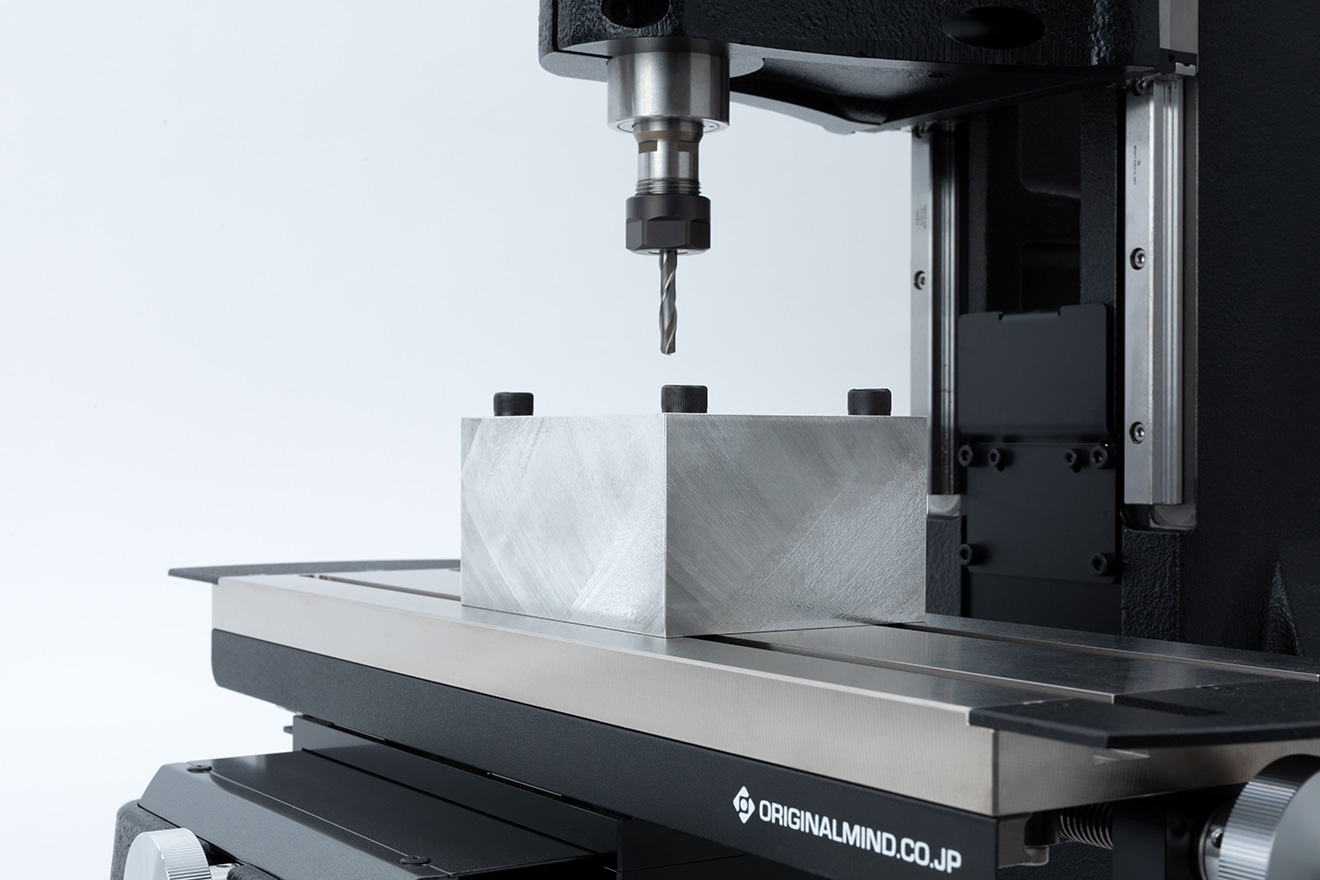

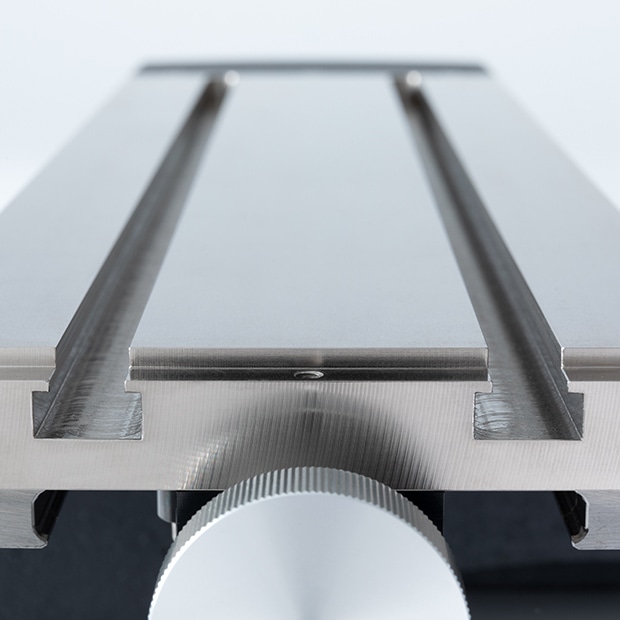

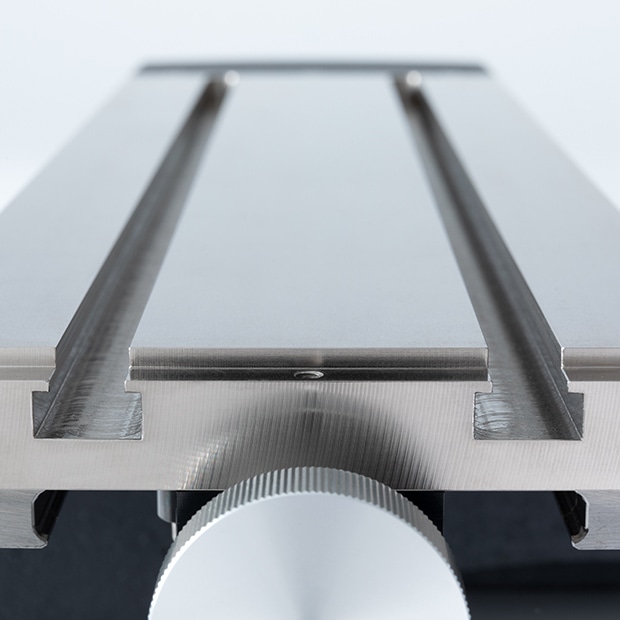

Adopts T-slot on work table

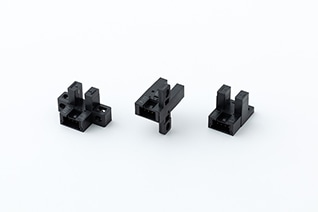

Collet chuck spindle included as standard

By adopting a T-slot, existing tools such as clamps and vices can be used as is. A variety of fixing methods can be Select according to the shape of the material and the processing.

A collet chuck type spindle with excellent precision and rigidity is available as an accessory.

Adopts T-slot on work table

By adopting a T-slot, existing tools such as clamps and vices can be used as is. A variety of fixing methods can be Select according to the shape of the material and the processing.

Collet chuck spindle included as standard

A collet chuck type spindle with excellent precision and rigidity is available as an accessory.

Engineer: Hidetoshi Gomi

Editor: Keita Fukasawa

Photographer: Kota Sugawara

Purchase a product

- KitMill AST200 main unit

- Controller (TRA250)

- Control software (USBCNCV4)

- Ball screw conversion set

- origin sensor set

- Aluminum handle set of 3

- high speed pulley

- Collet chuck for spindle Φ4,6

- step clamp set

- Flat Belt

- 85kg W850×D450×H850

External dimensions

(*1) The table can slide by the stroke of the X-axis by matching the left and right sides. (215mm)

Product composition

main unit

Controller (Standard: TRA250)

Wiring cables

Control software (USBCNC V4)

Ball screw conversion set

origin sensor set

Aluminum handle 3 piece set

high speed pulley

Collet chuck for spindle Φ4, Φ6

step clamp set

Click here to see what else you need to prepare.

Specifications

table size

table size

W: 425.8mm

D: 134mm

Mountable material height

Mountable material height

109.7mm

stroke

stroke

X-axis: 215mm

Y-axis: 119mm

Z-axis: 103mm

Materials that can be processed

Materials that can be processed

- resin

- FRP

- wood

- Aluminum alloys in general

- Brass

- steel material

spindle

spindle

Tool chuck type: Collet chuck type

Compatible shank diameter: Φ3, Φ4, Φ6, Φ8Compatible shank diameter: Φ4, Φ6

Rated speed: 5000 rpm

Rated speed: 8500 rpm when high speed pulley is installed

*High speed pulley sold separately

Motor Rated Power: 100W

feeding mechanism

feeding mechanism

Guide type: Linear guide

Feed type: Φ12 trapezoidal screw - plastic nut * Lead 2mm

When the Ball screw conversion set is installed: <XY axis only> Ball screw * Lead 4mm

* Ball screw conversion set is sold separately.

Maximum feed speed: <XY axis> 15mm/s (F900), < Z-axis> 7mm/s (F420)

Resolution: 1.25μm

Resolution Ball screw conversion set installed: <XY axis only> 2.5μm

* Ball screw conversion set is sold separately.

Processing Precision

Processing Precision

Error range when Ball screw conversion set is installed: ±0.02mm

The processing results are as follows:

<XY axis> +0.016mm ~ -0.013mm

< Z-axis> +0.001mm ~ -0.019mm

For details, including measurement methods, please see the machining accuracy measurement table at the bottom of the page.

Electrical department

Electrical department

Controller: TRA250 (special Specifications)

Power supply: AC100V50/60Hz

Power consumption: 200W

Compatible CAM

Compatible CAM

Cut2D / VCarve / Cut3D / MeshCAM / Fusion360 / PhotoVCarve

If you are looking for a CAM that is not listed here, you can find it here .

External dimensions

External dimensions

W: 552.5mm

D: 487.8mm

H: 513.8mm

weight

weight

67kg

Machining accuracy measurement table

Processing conditions

| Material | A2017 |

|---|---|

| tool | OM-SE2SM-2-6 |

| depth of cut | 0.1mm |

| feed rate | 300mm/min (F300) |

| Cutting speed | 60mm/min (F60) |

| feeding mechanism | <XY axis> Ball screw < Z-axis> Φ12 trapezoidal screw - Plastic nut |

Processing shape

Unit: mm

Measurement result

Error range: <XY axis> +0.016mm to -0.013mm

< Z-axis> +0.001mm to -0.019mm

Measurement using KEYENCE handheld probe 3D measuring machine XM-5000 .

| Measurement points | Actual measurements | ||||

|---|---|---|---|---|---|

| X20 | Y20 | X10 | Y10 | Z2 | |

| A | +0.007 | -0.013 | +0.003 | -0.011 | -0.019 |

| B | +0.006 | -0.001 | +0.007 | -0.008 | -0.019 |

| C | +0.004 | -0.001 | 0 | +0.015 | +0.001 |

| D | +0.010 | +0.010 | +0.005 | -0.001 | -0.001 |

| E | +0.002 | +0.005 | +0.002 | -0.012 | -0.016 |

| F | +0.005 | 0 | -0.002 | -0.004 | -0.003 |

| G | +0.016 | -0.003 | +0.008 | -0.004 | -0.018 |

| H | -0.002 | -0.001 | -0.003 | -0.006 | -0.012 |

| I | -0.001 | -0.007 | +0.007 | +0.006 | -0.002 |

Notes

- The product photo at the top of the page shows the optional Aluminum handle 3 piece set attached. Optional items are not included as standard, so please purchase them separately if necessary.

- Due to improvements, product Specifications and appearance are subject to change without notice.

Purchase a product

- KitMill AST200 main unit

- Controller (TRA250)

- Control software (USBCNCV4)

- Ball screw conversion set

- origin sensor set

- Aluminum handle set of 3

- high speed pulley

- Collet chuck for spindle Φ4,6

- step clamp set

- Flat Belt

- 85kg W850×D450×H850

Processing example

▲ A7075 (Aluminum) t5 × 100 × 100mm processing

Processing conditions

| Material | A7075 (Aluminum) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 0.5mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 0.5mm |

| feed rate | 300mm/min |

| Machining time | Approximately 75 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Processing conditions

| Material | C3604(Free-cutting brass) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 0.5mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 0.5mm |

| feed rate | 300mm/min |

| Machining time | Approximately 75 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Processing conditions

| Material | POM (Resin) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 2.5mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 5.0mm |

| feed rate | 300mm/min |

| Machining time | Approximately 15 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Processing conditions

| Material | white oak (wood) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 2.5mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 5.0mm |

| feed rate | 300mm/min |

| Machining time | Approximately 15 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Processing conditions

| Material | S50C (iron) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 0.2mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 0.2mm |

| feed rate | 300mm/min |

| Machining time | Approximately 195 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Processing conditions

| Material | A7075 (Aluminum) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 0.5mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 0.5mm |

| feed rate | 300mm/min |

| Machining time | Approximately 75 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Processing conditions

| Material | C3604(Free-cutting brass) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 0.5mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 0.5mm |

| feed rate | 300mm/min |

| Machining time | Approximately 75 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Processing conditions

| Material | POM (Resin) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 2.5mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 5.0mm |

| feed rate | 300mm/min |

| Machining time | Approximately 15 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Processing conditions

| Material | white oak (wood) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 2.5mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 5.0mm |

| feed rate | 300mm/min |

| Machining time | Approximately 15 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Processing conditions

| Material | S50C (iron) t5 × 100 × 100mm |

|---|---|

| CAD | Figure brain RAPID |

| CAM | Cut2D |

| tool | OM-SE2SM-2-6 |

| ■ Pocket processing | |

| depth of cut | 0.2mm |

| feed rate | 300mm/min |

| ■ Cutting out processing | |

| depth of cut | 0.2mm |

| feed rate | 300mm/min |

| Machining time | Approximately 195 minutes |

| ■ Notes | |

| spindle rotation speed | 8500rpm |

| Using step clamp set |

Other Processing example

Purchase a product

- KitMill AST200 main unit

- Controller (TRA250)

- Control software (USBCNCV4)

- Ball screw conversion set

- origin sensor set

- Aluminum handle set of 3

- high speed pulley

- Collet chuck for spindle Φ4,6

- step clamp set

- Flat Belt

- 85kg W850×D450×H850

What is Requirements for the operation of this product

Computer with USB port

A computer with a USB port is required to connect to the included controller (TRA250). For the operating environment, please see here .

CAD software

We do not handle CAD, so please prepare one that suits your purpose separately.

If you are using 2DCAM, please use one that can output DXF files, and if you are using 3DCAM, please use one that can output STL files.

CAM software

This is not included in the kit, so please prepare the appropriate item separately according to your needs.

CAM software comparison (explanatory article)

CAM software list (purchase page)

end mill

It is not included in the kit, so please purchase separately according to your purpose. When purchasing, please make sure that the shank diameter of the end mill that "KitMill" supports is the same as that of the end mill.

For first-time buyers, we recommend the following:

A great value set of 5 carbide square end mills for aluminum and plastic

*If you create an NC program using a text editor, you can run it without CAD/CAM. However, the NC programs for machining parts can be thousands of lines, or even tens of thousands of lines long, so please consider that CAD/CAM is Req'd when manufacturing parts.

Tools needed to assemble the kit

Hex wrench

A two-sided width of 1.5 to 8 mm is required. ( See product page )

+driver

You need No.00 and No.2.

-driver

You will need widths of 2mm and 5mm.

Soldering iron/solder

You will need it during wiring work.

nipper

Used for cutting and sheathing cables during wiring work.

spanner

You will need 7mm and 8mm widths on two sides.

Convenient things to have

scraper

Used to peel off materials fixed with double-sided tape.

double-sided tape

Used for fixing materials. We recommend the type that can be pasted and easily peeled off.

others

Purchase a product

- KitMill AST200 main unit

- Controller (TRA250)

- Control software (USBCNCV4)

- Ball screw conversion set

- origin sensor set

- Aluminum handle set of 3

- high speed pulley

- Collet chuck for spindle Φ4,6

- step clamp set

- Flat Belt

- 85kg W850×D450×H850

Introducing the performance comparison of the "KitMill" series and the differences with 3D printers.

You can compare the Specifications of all models in the "KitMill" series

Introducing the machining procedure of "KitMill" using KitMill CL100 as an example.

"KitMill" series warranty terms

To the warranty and support contents of "KitMill" series

Introducing partner companies and Fab spaces where our products are installed

Introducing works created using our products

Introducing the performance comparison of the "KitMill" series and the differences with 3D printers.

Introducing the machining procedure of "KitMill" using KitMill CL100 as an example.

Warranty and support details

Introducing works created using our products

Tour reservation

Tour reservation

We are accepting reservations for tours for customers who are considering purchasing the "KitMill" series of benchtop CNC milling machine. After our staff explains the product, we will demonstrate machining with "KitMill." We accept reservations for three slots per week, with each slot lasting one and a half hours from 13:30 to 15:00. Please feel free to apply.

Product catalog

Product catalog

You can view the Specifications of all "KitMill" series products.

Purchase a product

- KitMill AST200 main unit

- Controller (TRA250)

- Control software (USBCNCV4)

- Ball screw conversion set

- origin sensor set

- Aluminum handle set of 3

- high speed pulley

- Collet chuck for spindle Φ4,6

- step clamp set

- Flat Belt

- 85kg W850×D450×H850